Two waste receptacles, one red and labeled 'recycling,' the other brown and labeled 'landfill,' are not an uncommon sight around campus, and are utilized every day by students. However, students might not be aware of where their waste goes after they throw it out or recognize how their recycling practices could help improve campus recycling as a whole.

On average, USC produces around 20 tons of waste per day, according to USC Waste and Recycling Manager Dameon Hopkins.

According to Director of Sustainability Larry Cook, annually, waste management services are able to divert around 30%, or 1500 tons of total waste, from landfills. Diverted waste includes mostly recycled and some composted material, which is managed by the university before being sent to third-party companies for disposal.

“There are schools that are lots better than that, there are schools that are lots worse than that,” Cook said. “We certainly have room to improve."

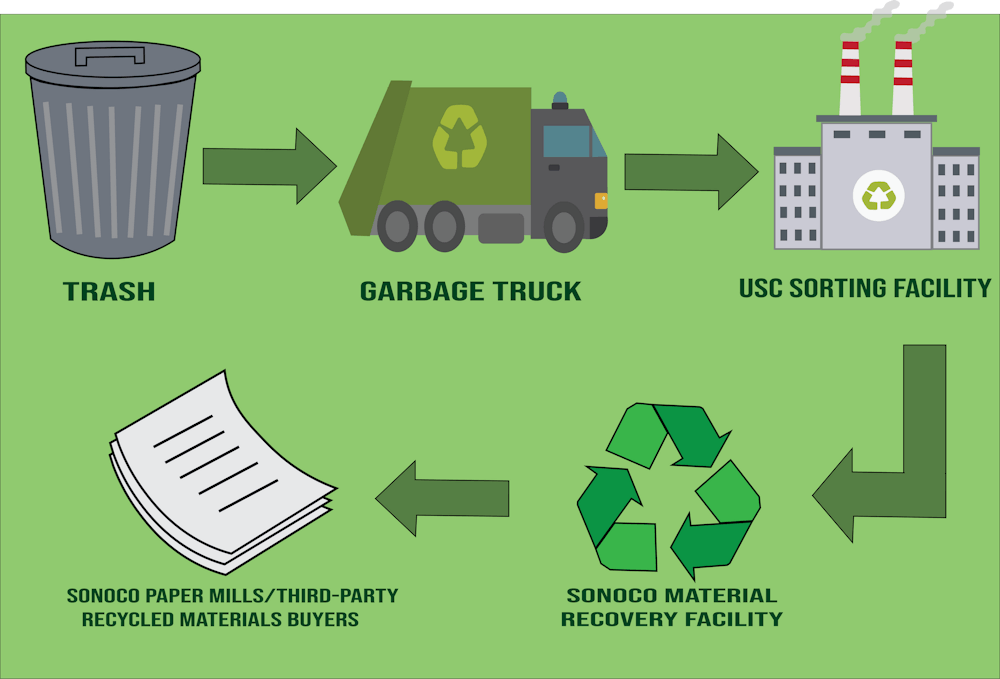

After municipal solid waste, or everyday trash, is thrown away, it is picked up by university-operated front-loading garbage trucks and taken to the Richland County Solid Waste Landfill, while recyclables are transported by cargo vans to USC's waste sorting facility. Columbia residents and students living off-campus can also drop off their recyclables at the sorting facility, Hopkins said.

Though these locations are around campus for students and Columbia residents alike to drop off their recycled waste, many people are unaware of these drop-off bins, Hopkins said.

"Some of these apartment complexes and/or subdivisions that cater to college kids, they don't have recycling programs," Hopkins said. "If we could, as a university, reach out, we could probably make a big difference, because some folks off campus want to recycle, but they don't know what to do with it, especially not being from the greater Columbia area."

Municipal recyclable materials such as plastics, aluminum, glass, paper and cardboard are sent to the waste sorting facility, where all materials are hand-sorted to the commodity level to be sent to different vendors, Hopkins said.

After sorting, most recycled materials are then taken to a material recovery facility, or MRF, run by international packaging and recycling company Sonoco. Sonoco has a large recycling division and runs a "state-of-the-art" recycling and recovery facility in Columbia, according to Cook.

Sonoco receives recycled material from municipalities in Columbia and surrounding counties as well as the university. USC’s material provides only a small amount of the total volume of material Sonoco processes as the plant handles "hard-to-even-contemplate volumes" of recyclables, Cook said.

USC has worked with Sonoco for many years and in different ways to increase recycling on campus, Sonoco Plant Manager Logan Carpenter said.

Sonoco’s Columbia plant runs a dual recycling facility and MRF, in which recycled material, such as material the university provides, is separated through a mix of automated and hand-sorting. Automation in material sorting can drastically increase efficiency, Carpenter said.

“Automation is a part of (sorting),” Carpenter said. “I would say Columbia is kind of middle of the pack. We do have a good mix (of) our personnel on the line ... but at the end of the day, if you think about throughput and recovery rate, some of these machines here are (like) having eight people on one conveyor.”

After sorting, Sonoco sends the majority of the paper and fiber products it recovers to its paper mills in Hartsville, South Carolina, where the organization is headquartered. Non-fiber materials such as plastic or aluminum are baled and distributed to Sonoco partner companies, where finished products are created.

“In a way, our Sonoco paper mills, even though we're the same company, are our customers. We are their suppliers,” Carpenter said.

While USC’s recycling program has improved over the years, there are still some economic efficiency roadblocks in the process, Cook said.

“We're middle of the road,” Cook said. “We do some things really well, we've got plenty of room for improvement. This is a challenging area for a couple of reasons that every collegiate program, is facing. Number one is recycling is different everywhere you go, because certain materials (have) economic value only if there's an outlet for it really nearby.”

As recycling at USC has grown, students have become more educated about how and what to recycle, therefore decreasing the levels of contamination in recycled waste, Hopkins said. When bags of recycled waste contain non-recyclable or dirty items, it can potentially result in the entire bag being sent to the landfill. When students know what they can recycle in campus receptacles, recycled waste contamination can be alleviated.

“When we first started hands on sorting, probably around 2015 when the university wasn't as educated, we had a lot more contamination,” Hopkins said. “But now, with our color system (and) our waste streams, the contamination rate is more minimal in our recycling bags.”

One way recycling could be further improved would be to raise awareness of recycling drop-off spots, Cook said. Though the Office of Sustainability and Sustainable Carolina work to educate off-campus students about drop-off locations, there are challenges unique to the university setting, Cook said.

“Awareness is a really challenging thing,” Cook said. "And we're a little bit limited in the capacity without having that central, comprehensive location…one of the real challenges with education on any college campus is the constantly changing student population, and so we continue to try and push this information out.”

Recycling drop-off locations are currently located at USC’s sorting facility at 1220 Catawba St., behind Green Quad, Capstone and Columbia Hall, but Cook believes the drop-off site would gain more traction at the sorting facility, he said.

“We would like to envision a really functional, comprehensive drop off location at the sorting site,” Cook said. “That's just the most convenient place, since the operation is already occurring there. But also, there's the potential of people seeing the design, (the) behind the scenes work. And there's just an added level of trust and certainty that this operation is running smoothly to kind of be transparent about how it's happening.”